0

+

Contact Us

(+021) 117 871

A new process of molding these technical textiles of natural fiber into a new class of material made from special modified Synthetic Resins and renewable Natural Fibers, like Jute, Kenaf, Hemp, Flax, Ramie & Nettle fibers, designed for diversified use in building & construction, interiors / exteriors and furniture applications, etc

Using TCT technology |Low Carbon Footprint| Cost Effective|

Sustainable Replacement for WOOD

- Professional Carpentry

- High-Quality Materials

- Home Interiors and Exterior Designing

- Wall Cladding

- Louvers and Fixtures

- Flooring Tiles

- Furniture

- Portable Homes

- Wiring Conceal Applications

Customer Satisfaction

99%

Quality Craftsmanship

92%

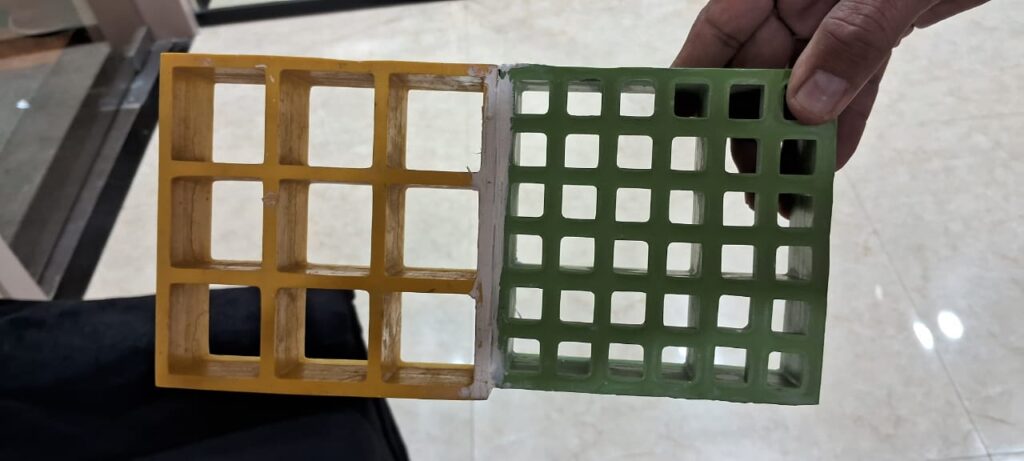

FRP APPLICATIONS

Introducing Green Metal one of the strongest commercial materials available is HolyWood GFRP It is stronger in many ways than conventional construction materials. FRP's toughness allows thin sections to be used; stiffness can be acquired by using structural core materials, without substantially increasing weight.

Our Fiber Reinforced Polymers (FRP) are unique composite materials in many respects. they can be formulated to be corrosion, abrasion, and UV resistant, as well as, smoke and fire retardant. FRP are often a cost-effective choice in many industrial applications; they have long life cycles and have demonstrated durability in stringent environments with reduced maintenance costs. Here are five reasons FRP stand out when compared to metals and metal alloys.

1. High Strength-to-Weight Ratio– FRP are lightweight and strong; they posses a vast

range of mechanical properties, including tensile, flexural, impact and compressive

strengths. When compared to most other metals they can deliver more strength per unit of

weight then most metals. Their light weight also lends itself well to logistics—it’s easier to

ship and install.

2. Customizable- Every industry has unique problems to solve. With FRP engineers have

the ability to tailor or modify the design of their FRP to meet their specific requirements.

For example, consider the benefits of altering resin, glass content to optimize your

corrosion and or abrasion resistance—you can’t do this with metal.

3. Anisotropic- Engineers can maximize the performance and efficiency of the structure

when they take advantage of the inherent anisotropic properties of FRP. Because the

maximum strength is in the direction of the fiber reinforcements engineers can optimize

the design to optimize the materials and the overall performance of the structure.

4. High Tensile Strength with Low Modulus of Elasticity-FRP have high tensile strength

due to its composite properties. Engineers can specify unique resin, fiber-reinforcement

compositions when working with FRP manufactures. The design control inherent to FRP

will enhance performance and can only be realized when working with composites, not

metals.

5. Ability to Form Complex Shapes- Engineers can harness ultimate design flexibility

when using FRP—an advantage over traditional materials such as metal, concrete, and

wood. When you integrate FRP design into your project into your project also consider the

added benefits of part consolidation, noise reduction and streamlined design.

There are many other reasons one should consider using FRP. they offer high dialectical

strength, thermal cycling, dimensional stability, impact resistance, low coefficient of

friction, and do not require cathodic protection—just to name a few.

Our Products

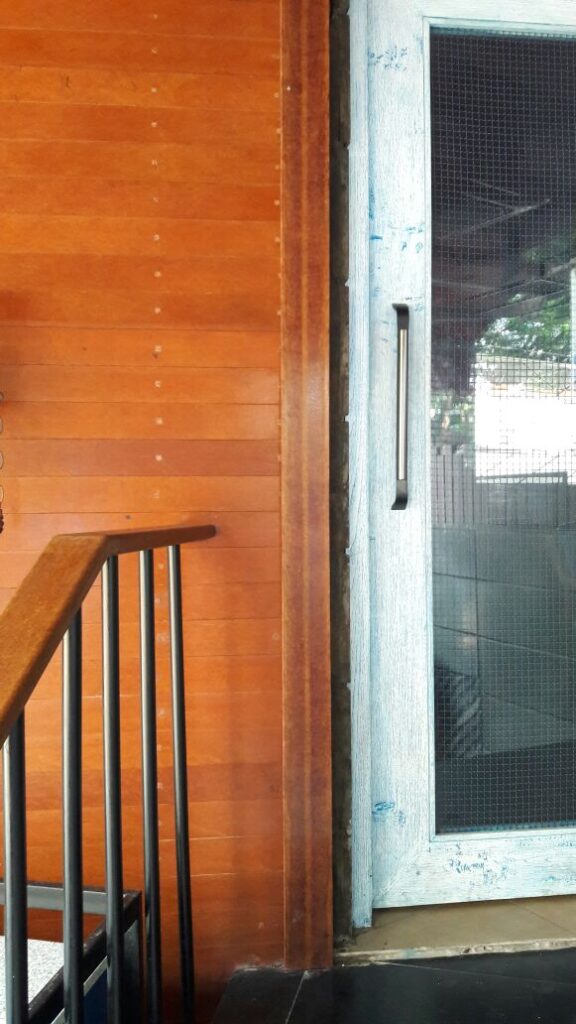

Doors

BUILDING – CLADDING & EXTERIORS

SCREENS & GRILLS

DECKING/ PATHWAYS

FENCING & GATING SYSTEMS

PARTITIONS

PERGHOLAS / CABANAS / TRELLISES

PARTITIONS

LOUVERS

PARTITIONS

NATURAL FIBER COMPOSITES & PROPERTIES

Flame retardant

Water Resistant

Termite proof

Resistance to fatigue & corrosion

UV resistance

Energy Saving

Low carbon footprint

Superior mechanical properties

Reducing material costs

Electrical insulation

Can be cut, sawn, planed, drilled, nailed, shaped etc.

Can be painted, polished, varnished, coated, etc

Why holywood composite ?

-

GREEN TECHNOLOGY

Plastics & Composites • Are eco-friendly • Use low energy in per kg conversion • Replace wood and metals HEMP ECOPLY has extremely low

-

LOWEST CARBON FOOTPRINT

Carbon Footprint. • Green Resins (Organic) Synthetic Resins (Plastics) • Natural Fibers (annually renewable) • No cutting wastage (cut-to length) • Promoting Agriculture

Explore our best carpenter services

Personal Residence

Buildings

Lorem ipsum dolor sit amet consect adipiscing elit sed do eiusmod temp incididunt labore et dolore.